Backcountry skis in a bind

We pay plumbers and electricians a lot. This is largely because we’re more likely to flood the downstairs neighbours or electrocute ourselves than they are. Some things are just better done by pros, and installing bindings on fjellski – as we call cross-country skis built for breaking trail in Norway – are considered by most to be one of those things. There’s a lot to go wrong. Voiding your warranty is just the start of it; failing to seal the holes after pre-drilling properly, using the wrong template, mounting crookedly – maybe it’s best to make some things someone else’s problem. But if you’ve read this far, you’re probably thinking of doing it anyway. And we’re certainly not going to stop you. Read on.

Choosing bindings

So many choices. NNN BC? 75mm? Xplore? What about cables? Learn about the options!

Find the balance point

The first thing to do is to find the balance point. This is found, of course, by balancing the ski. Put the ski on the edge of a ruler, the back of a knife, or a right angle, and then find the point where the ski’s completely balanced by itself. Mark it with a pen or pencil. This must be done on both skis; there may be slight differences between them. If the skis have different balance points, mark a point equidistant between the two points on each ski: this is the average balance point you’ll will be working from for the next step (you need the bindings mounted in the same place on each ski, even if the balance point isn’t identical; this is a perfectly acceptable compromise).

Once you’ve found and marked the balance point, you can use a mounting jig or a paper template to measure where to drill the holes.

The right glue – PU

On Åsnes skis, use a single-component, solvent-free polyurethane glue in the screw holes when mounting bindings. PU glue was developed to be a universal adhesive for gluing wood to materials such as metal, plastic, rubber, and wood. It hardens with the help of humidity, moisture in the material, and the materials being glued together. The bond can actually be strengthened if you spray it lightly with water before mounting the bindings. PU also expands during the curing process, which makes it particularly suitable for sealing the pre-drilled holes bindings are screwed into.

Grunnlaget for vår anbefaling av lim

Tests and the extensive experience we’ve gained from all the skis we’ve supplied for expeditions, hard mountain use and NATO forces, confirm that polyurethane glue (PU) works much better than ordinary wood glue. Its composition is also resistant to water. If you unscrew bindings from an old ski, you typically see screw holes brown with rot and red with rust thanks to poor sealing. You want to avoid this; it’s is essential to prevent water such as melting snow penetrating the wooden interior, which can damage the flex and torsional properties of the construction irreparably. If the principle purpose of the glue is to bind the bindings, PU glue’s good: it’s been shown to have a capacity for holding screws in the skis some 20% stronger than comparable glues.

Drilling the holes

For drilling, we use a 3.6mm x 9mm bit, with a good-sized lip to stop them going too deep, made for mounting ski bindings. Suppliers such as Wintersteiger, Rottefella, Montana, among others, make bits like these for specialised ski workshops.

Use a mounting jig

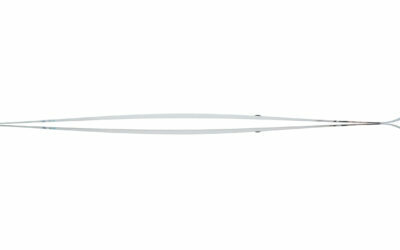

We always recommend using a drilling jig when pre-drilling holes for the binding screws. It’s safer. Always check that the drill’s position follows the recommendations of the binding manufacturer and the ski company before you drill.

Photo: Rottefella

Check the screws that come with the binding

Before you drill and screw the binding onto the skis, it’s important to check that the screws that come with the binding are correct and that they aren’t, for example, too long. On children’s skis and shorter skis, especially, you should be very careful to check the length. If you screw a screw through a ski, it’s your responsibility!

Tightening the binding

Tighten the binding to the ski by hand or with a low torque on the drill. Always finish tightening by hand. You want the screws flush and no more – certainly not twisting freely.

Rottefella bindings

Voilé bindings

Choosing bindings for cross-country BC skis

Not certain which bindings choose for cross-country skiing in the backcounty? Confused by the difference between NNN-BC or 75mm bindings? Cable-curious? Find all the answers here!

Tailoring long skins for alpine touring

Wondering how to tailor your skins for alpine touring? Here’s an overview – care and trimming long skins for touring skis.

So – what exactly is a skin, anyway?

Skins are more than a strip of carpet with glue on the back. They’re tools designed to help us in pursuit of pristine snow, perfect lines, and/or solitude. Something this magical demands a proper description of how it’s made.

Everything you need to know about camber in cross-country BC skis

Lurer du på hva hva disse begrepen betyr og hva dette har å si for skiene dine? Ikke noe problem! Vi har laget en inngående forklaring på hva dette er og hvilken funksjon det har for skiene.

Tuning steel edges

Tuning and maintaining your steel edges is pretty simple if you have the tools. If you don’t, you can take them to a workshop to have them machined. Everyone has an opinion when it comes to grinding. And much is a matter of preference. But it’s worthwhile bearing in mind that ski designers made their decisions for a reason…

Waxless or waxable skis?

Buying new skis and not sure whether to choose waxable or waxless bases? Maybe you think grip wax is tricky. Maybe you find the convenience of waxless is enticing. Here’s your path through the pros and cons (and the science!) of both…