What are sidewalls?

The sidewall is a strip of dense plastic incorporated into the ski construction. It sits between ski core and topsheet along the ski’s length, over the edges of the sole. Its primary purpose is to prevent damage to the ski core, maintaining the ski’s overall integrity. If you end up in a tangle of limbs and skis falling foul of a steep and icy snowmobile track, it’s the sidewall that prevents the steel edge of one ski from exposing the wooden core of the other along the side. Likewise, if you drop your skis on the ground or hit a stump shedding speed in a forest, the core will remain undamaged when the sidewall takes the brunt.

ABS-sidewalls

Many skis made in “sandwich” or “semi-cap” construction have ABS sidewalls. This is acrylonitrile-butadiene styrene – a type of thermoplastic that’s become the standard in good skis. It offers good stability, it protects against water penetration, and protects your sides from wear and stray steel edges. ABS sidewalls are associated with higher costs for ski manufacturers. But they add many desirable properties. Since this type of sidewall is highly strong and dense, it confers the ski torsional stiffness and better edge grip. Torsional stability is resistance to twisting and bending – a positive attribute when switching from edge to edge, initiating a turn, or edging your skis to carve or shed speed with control. Skis with ABS sidewalls have better characteristics when driven hard, on edge, than skis without. They’re also more resistant to damage, water penetration and easier to repair should you damage the steel edge – even if the skis are somewhat heavier and more expensive to produce.

ABS sidewalls. Photo: Crister Næss v/ Åsnes

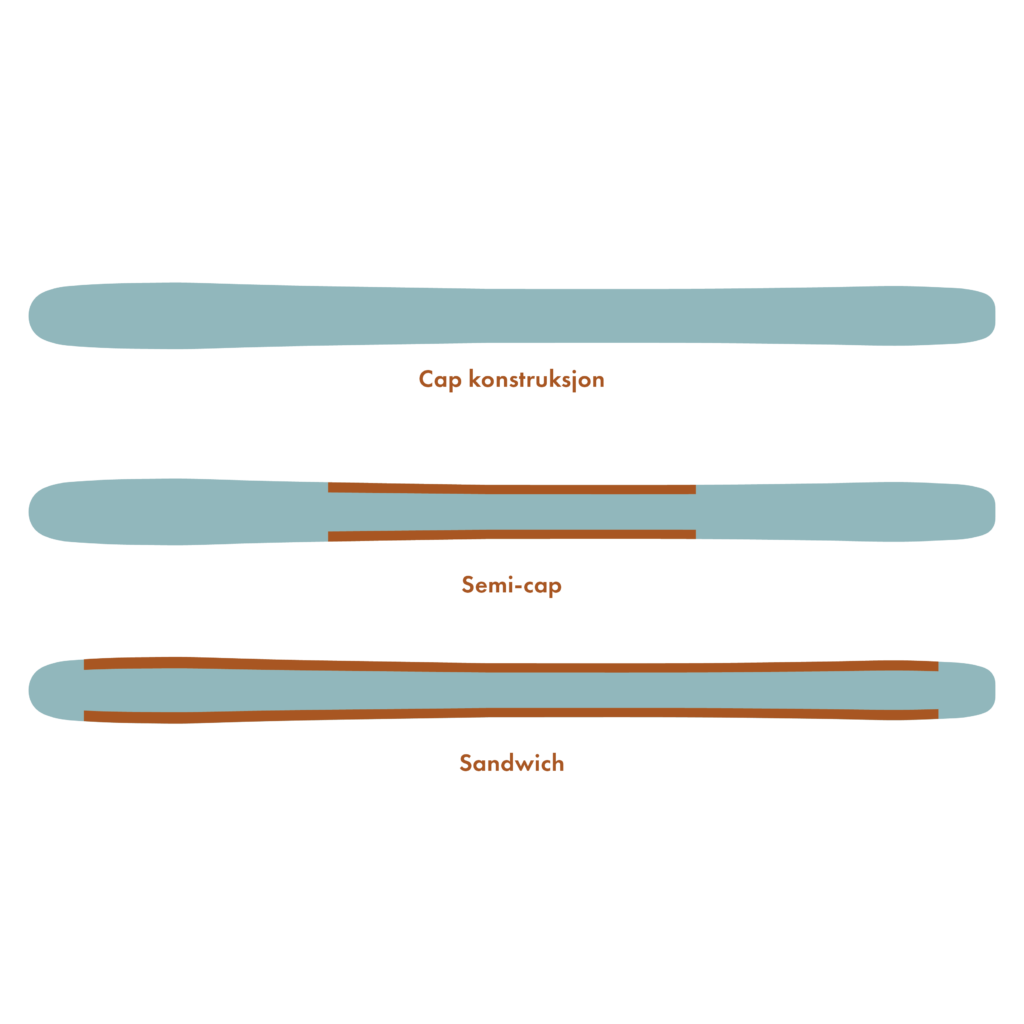

The three different kinds of sidewall construction

Today, it’s reasonable to say that factory-made skis come with three different types of sidewall construction. The difference between them is a question of how much of the ski is covered along the length. As we’ve seen, the ski’s sidewall determines its torsional rigidity – its willingness to twist and bend from edge to edge. Having a ski with high torsional stiffness is an asset when you’re edging your skis. It’s about control. A good sidewall mitigates edge compression. Imagine a dent at the edge of your base caused by, say, stomping hard on a concealed tree stump. The base of your ski is compressed in that spot, no longer flat. The dent has bent the sidewall up so far that the edge of the ski is distorted. Perhaps the topsheet has even come free. This is edge compression. It can be staved off by the density of an adequate sidewall, preventing the ski from over-bending and the core losing its integrity in that spot..

“Sandwich” construction

Skis with sandwich construction have the greatest torsional rigidity, longevity, and ruggedness. The entire sidewall is buttressed, making it hardy and resistant to twisting from edge to edge.

Cap construction

Where the sandwich construction is all about covering and buttressing along the ski’s edge, in a cap construction ski, there’s nothing there other than the topsheet . Think “marzipan on a cake” sealing the contents, in this case shrunk to the core, down along the walls to the steel edge and sole. This results in a slimmer appearance, perhaps more rounded, depending on the kind of ski.

Semi-cap construction

It probably isn’t difficult to work out what semi-cap construction entails: the design aims to exploit the advantages of both cap and sandwich with a partially-covered core buttressing the ski’s effective edge.

Myths about skins – busted

Not everything you hear about skins is right. We’re here to dish the skinny on skins, busting some misconceptions about your skins, complete with counter-evidence and tips garnered through trial and error in real snow, by real skiers, in actual Norway.

What are carbon skis really?

Is there really any such a thing as a “carbon ski”? Well… no. We explain why – and what carbon and fiberglass actually mean to ski construction.

Tailoring long skins for alpine touring

Wondering how to tailor your skins for alpine touring? Here’s an overview – care and trimming long skins for touring skis.

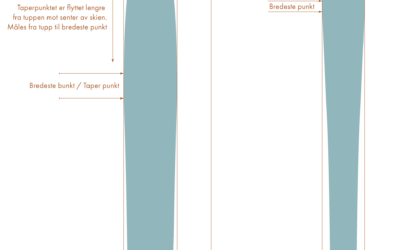

Rocker, nordic rocker, taper and sidecut

Reading the specs, we read about rocker, nordic rocker, taper, and sidecut. If you don’t know what these things are, or what effect they have on the properties of your skis, read on as we break it down…

Choosing the right skin

Short skins have revolutionised trips to the backcountry on nordic skis. Long skins get you to the top. You can nail gliding, climbing, pulling, gripping, poor conditions, good conditions, days when you’re feeling too lazy to wax. We break down material, length, width, care, and everything else you’ll want to know.

Everything you need to know about camber in cross-country BC skis

Lurer du på hva hva disse begrepen betyr og hva dette har å si for skiene dine? Ikke noe problem! Vi har laget en inngående forklaring på hva dette er og hvilken funksjon det har for skiene.